The journey of plate rolling machines is a fascinating tale of innovation and engineering. These machines, pivotal in metal manufacturing, have transformed immensely from their early mechanical versions to the sophisticated CNC-controlled systems of today. Companies like Himalaya Machinery in India have played a significant role in this evolution. This article explores the past, present, and future of plate rolling machines, shedding light on their impact on the metal manufacturing industry.

The Early Days of Plate Rolling Machines

Imagine a time when metalworking relied heavily on manual labor and rudimentary tools. The earliest plate rolling machines were simple mechanical devices, powered by hand or animal. These early machines were a significant advancement, enabling more uniform and precise bending of metal plates compared to manual methods. They were essential in shipbuilding, railway construction, and the manufacturing of boilers.

Key Innovations in Plate Rolling Machines

Over time, the demand for more complex and precise metal shapes led to numerous innovations in metal rolling machines. The introduction of steam power in the 19th century was a game-changer. Machines became larger and more powerful, capable of rolling thicker and wider plates.

The Introduction of Electrical Power

The next big leap came with the advent of electrical power. Electric motors replaced steam engines, providing more reliable and controllable power. This period also saw the development of more sophisticated control mechanisms, enabling better precision and repeatability in metal forming.

The Advent of CNC Rolling Machines

The 20th century brought about the digital revolution, and the metalworking industry was no exception. The introduction of CNC (Computer Numerical Control) rolling machines marked a significant milestone. These machines are controlled by computer software, allowing for incredibly precise and complex shapes to be formed with minimal human intervention.

Benefits of CNC Rolling Machines

CNC rolling machines offer numerous advantages:

- Precision: They can execute complex designs with high accuracy.

- Efficiency: Reduced need for manual adjustments speeds up the production process.

- Consistency: Every product can be identical, reducing waste and ensuring quality.

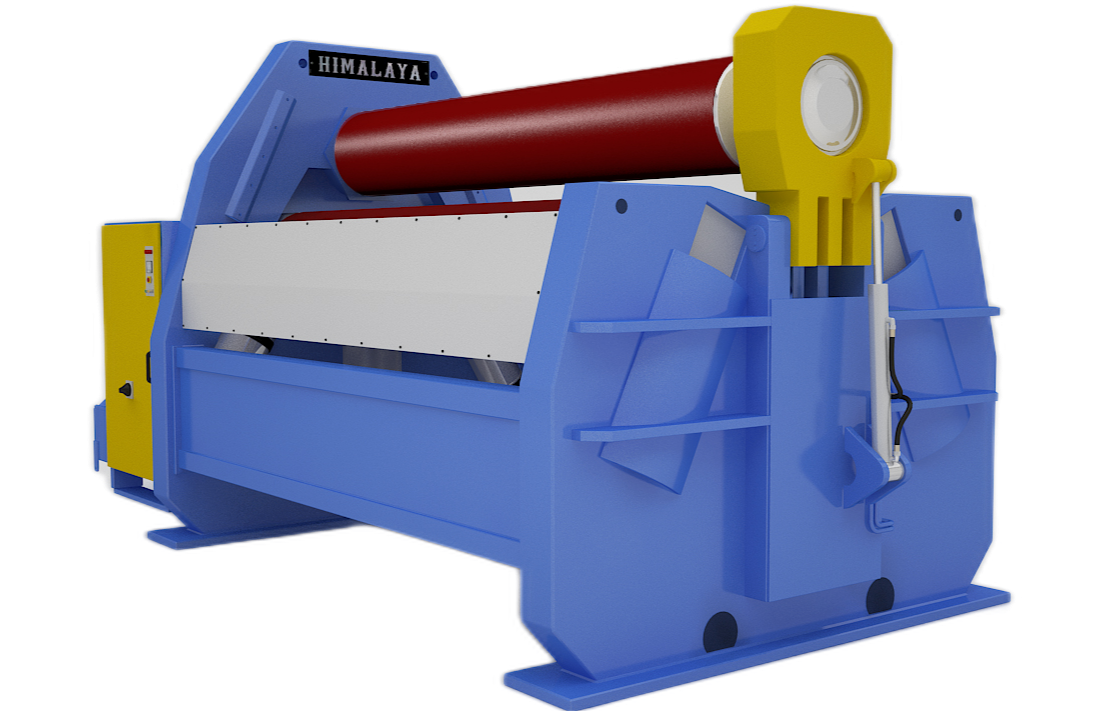

How Himalaya Machinery Shaped the Industry

Himalaya Machinery, a prominent heavy engineering company in India, has been at the forefront of developing advanced plate rolling machines. They have combined traditional engineering expertise with cutting-edge technology to produce some of the most efficient and reliable machines on the market.

Innovations by Himalaya Machinery

Himalaya Machinery has introduced several innovations, such as hybrid systems that combine hydraulic and CNC controls for enhanced flexibility and precision. Their commitment to quality and continuous improvement has made them a trusted name in the industry.

Current Trends in Plate Rolling Machines

Today’s plate rolling machines are more advanced than ever. Key trends include:

- Automation: Increasing use of robotic systems to automate loading and unloading of plates.

- Integration: Machines that integrate with other manufacturing processes for seamless production lines.

- Smart Technology: Incorporation of IoT (Internet of Things) for real-time monitoring and predictive maintenance.

Understanding Plate Rolling Machine Prices

The price of a plate rolling machine varies based on several factors:

- Size and Capacity: Larger machines that can handle thicker and wider plates are generally more expensive.

- Technology: CNC and automated machines command higher prices due to their advanced features.

- Brand and Quality: Well-known brands like Himalaya Machinery often have higher prices due to their reputation for quality and reliability.

Factors Influencing Prices

- Materials: The quality of materials used in the construction of the machine.

- Features: Additional features like automation, CNC control, and advanced safety measures.

- Customization: Custom-built machines tailored to specific needs can be more costly.

Future Prospects of Plate Rolling Machines

The future of plate rolling machines looks promising, with several exciting developments on the horizon. Advances in artificial intelligence and machine learning are expected to bring about even more automation and efficiency. Smart factories, where machines communicate with each other and adjust operations autonomously, are becoming a reality.

Potential Innovations

- AI Integration: Machines that can learn from data to optimize processes.

- 3D Rolling: Advanced techniques to create more complex three-dimensional shapes.

- Eco-Friendly Designs: Machines that consume less energy and produce less waste.

The Role of Technology in Metal Rolling Machines

Technology has always been a driving force behind advancements in metal rolling machines. From the first mechanical rollers to today’s CNC machines, each technological leap has brought about significant improvements in efficiency, precision, and capabilities.

Impact of Digitalization

Digitalization has had a profound impact, allowing for better design, control, and maintenance of machines. Predictive maintenance, powered by IoT, helps in identifying potential issues before they lead to downtime, ensuring smoother operations.

Sustainability and Plate Rolling Machines

As industries worldwide focus more on sustainability, the metal manufacturing sector is no exception. Modern plate rolling machines are being designed with sustainability in mind. This includes using more energy-efficient motors, reducing waste through precision engineering, and developing systems that require less maintenance.

Green Manufacturing

Green manufacturing practices are becoming more prevalent, with a focus on reducing the carbon footprint of metalworking processes. This is achieved through innovations in machine design and operation, such as using renewable energy sources and recycling metal scraps.

Challenges Facing the Industry

Despite the many advancements, the plate rolling machine industry faces several challenges:

- High Initial Costs: Advanced machines can be expensive, making it difficult for smaller companies to invest.

- Skill Gap: Operating modern machines requires skilled labor, and there is a shortage of qualified personnel in some regions.

- Maintenance and Downtime: Ensuring machines are well-maintained to avoid costly downtime is a constant challenge.

Conclusion

The evolution of plate rolling machines from simple mechanical devices to advanced CNC-controlled systems is a testament to human ingenuity and the relentless pursuit of improvement. Companies like Himalaya Machinery continue to drive the industry forward, embracing new technologies and meeting the ever-growing demands of the metal manufacturing sector. As we look to the future, the possibilities for innovation in plate rolling machines are endless, promising even greater efficiency, precision, and sustainability.