IMARC Group’s report titled “Lathe Machines Market Report by Type (Vertical Lathes, Horizontal Lathes), Operation (Conventional Lathes, CNC Lathes), Capacity (Heavy Duty, Medium Duty, Low Duty), End User (Automotive, General Manufacturing, Transportation, and Others), and Region 2024-2032“. The global lathe machines market size reached US$ 25.2 Billion in 2023. Looking forward, IMARC Group expects the market to reach US$ 37.5 Billion by 2032, exhibiting a growth rate (CAGR) of 4.4% during 2024-2032.

Factors Affecting the Growth of the Lathe Machines Industry:

- Automation and Industry 4.0 Integration:

Automation and the integration of Industry 4.0 technologies have significantly influenced the lathe machines market. Industry 4.0 emphasizes the use of advanced automation, data exchange, IoT (Internet of Things), cloud computing, and AI (Artificial Intelligence) to enhance manufacturing processes. In the context of lathe machines, automation allows for greater precision, efficiency, and consistency in operations. Automated lathe machines can perform complex tasks with minimal human intervention, leading to higher productivity and reduced operational costs. Real-time data monitoring and analytics provided by Industry 4.0 technologies enable predictive maintenance, minimizing downtime and enhancing machine lifespan. Manufacturers are increasingly adopting automated lathe machines to stay competitive in a rapidly evolving market, where speed and precision are critical.

- Significant Technological Advancements in CNC Lathe Machines:

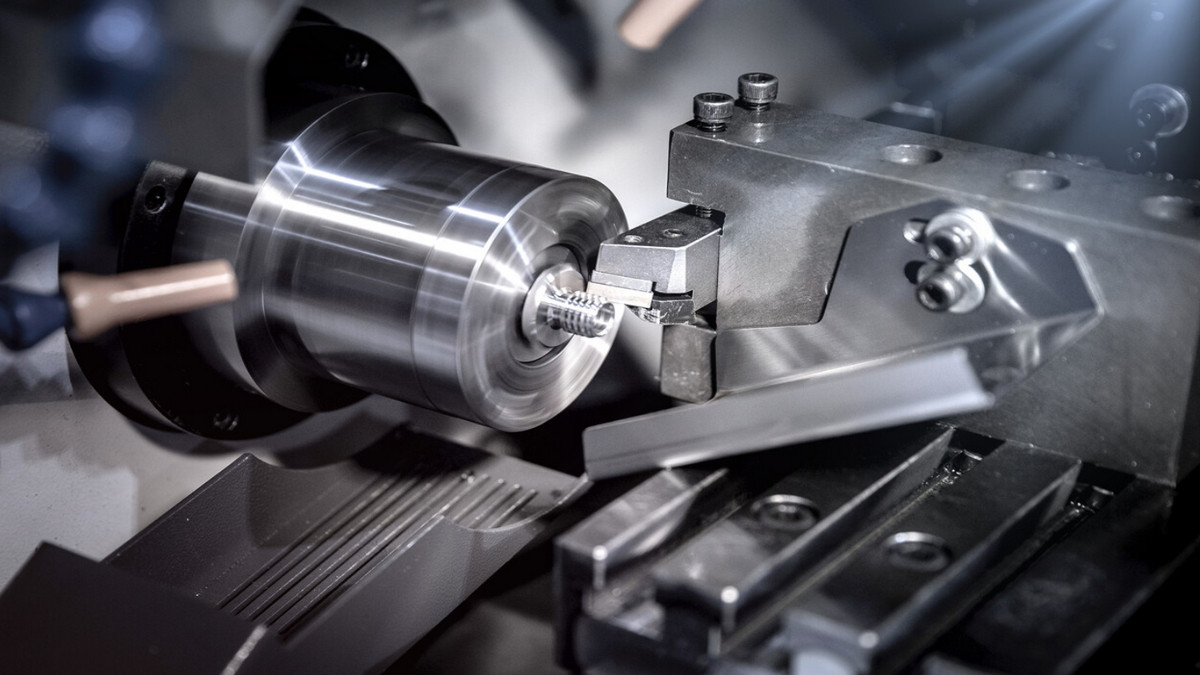

Continuous technological advancements in Computer Numerical Control (CNC) lathe machines have been a significant driver of market growth. CNC technology allows for precise control of machining operations through computer programming. Modern CNC lathe machines offer advanced features such as multi-axis machining, live tooling, and high-speed capabilities, which cater to diverse manufacturing needs across industries such as automotive, aerospace, and electronics. Improved software interfaces and programming languages simplify machine operation and setup, reducing lead times and enhancing flexibility in production. Moreover, CNC lathe machines support the machining of complex geometries and materials, expanding their application scope. Manufacturers are investing in CNC lathe machines to improve efficiency, quality, and scalability in production, driving market expansion globally.

- Rise in Demand from End-Use Industries:

The increasing demand for precision components from end-use industries such as automotive, aerospace, electronics, and healthcare is fueling the growth of the lathe machines market. Lathe machines are essential for manufacturing critical components such as shafts, bushings, gears, and surgical implants with high accuracy and consistency. As these industries evolve to meet consumer demands for advanced technology and innovation, the requirement for efficient machining solutions such as lathe machines grows. Additionally, sectors such as renewable energy and construction benefit from lathe machines for manufacturing specialized components. Emerging markets in Asia-Pacific and Latin America are witnessing rapid industrialization and infrastructure development, further driving the demand for lathe machines.

Leading Companies Operating in the Global Lathe Machines Industry:

- DMG Mori Co. Ltd

- Doosan Machine Tools Co. Ltd.

- EMAG GmbH & Co. KG

- Fair Friend Group

- Haas Automation Inc.

- Hardinge Inc.

- HMT Machine Tools Limited (HMT Limited)

- Hurco Companies Inc.

- JTEKT Corporation

- Macpower CNC Machines Limited

- Mazak Corporation

- Okuma Corporation

- SMEC CO. LTD.

For an in-depth analysis, you can refer sample copy of the report: https://www.imarcgroup.com/lathe-machines-market/requestsample

Lathe Machines Market Report Segmentation:

By Type:

- Vertical Lathes

- Horizontal Lathes

Horizontal lathes dominate the market due to their versatility in handling a wide range of workpiece sizes and shapes, making them ideal for diverse industrial applications.

By Operation:

- Conventional Lathes

- CNC Lathes

CNC lathes hold maximum number of shares due to their ability to offer precise control, versatility in machining capabilities, and efficiency in production processes across various industries.

By Capacity:

- Heavy Duty

- Medium Duty

- Low Duty

Heavy duty represents the largest segment due to its capability to handle large-scale machining tasks and its versatility across industries requiring robust and high-performance machining solutions.

By End User:

- Automotive

- General Manufacturing

- Transportation

- Others

On automotive dominates the market due to its extensive reliance on precision manufacturing of components such as shafts, gears, and engine parts, which are efficiently produced using lathe machines.

Market Breakup by Region:

- North America (United States, Canada)

- Asia Pacific (China, Japan, India, South Korea, Australia, Indonesia, Others)

- Europe (Germany, France, United Kingdom, Italy, Spain, Russia, Others)

- Latin America (Brazil, Mexico, Others)

- Middle East and Africa

Global Lathe Machines Market Trends:

The adoption of hybrid manufacturing techniques, combining traditional machining with additive manufacturing processes such as 3D printing, is influencing the lathe machines market. Hybrid machines integrate subtractive and additive capabilities, allowing manufacturers to create complex geometries and optimize material usage. These machines enhance flexibility in prototyping, customization, and small batch production, catering to diverse industry needs. As additive manufacturing gains traction for producing intricate parts, the demand for lathe machines capable of integrating these technologies is increasing. Other than this, there is a growing emphasis on energy efficiency and sustainability in manufacturing operations, driving innovations in lathe machine design. Manufacturers are developing energy-efficient models that reduce power consumption without compromising performance. Additionally, advancements in lubrication systems and materials contribute to minimizing environmental impact and operational costs. Sustainable practices such as recycling machine components and reducing waste during production are becoming critical considerations for businesses, influencing their choice of lathe machines that align with green manufacturing initiatives.

Note: If you need specific information that is not currently within the scope of the report, we will provide it to you as a part of the customization.

About Us:

IMARC Group is a leading market research company that offers management strategy and market research worldwide. We partner with clients in all sectors and regions to identify their highest-value opportunities, address their most critical challenges, and transform their businesses.

IMARCs information products include major market, scientific, economic and technological developments for business leaders in pharmaceutical, industrial, and high technology organizations. Market forecasts and industry analysis for biotechnology, advanced materials, pharmaceuticals, food and beverage, travel and tourism, nanotechnology and novel processing methods are at the top of the companys expertise.

Our offerings include comprehensive market intelligence in the form of research reports, production cost reports, feasibility studies, and consulting services. Our team, which includes experienced researchers and analysts from various industries, is dedicated to providing high-quality data and insights to our clientele, ranging from small and medium businesses to Fortune 1000 corporations.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: [email protected]

Tel No:(D) +91 120 433 0800

United States: +1-631-791-1145