Gold has always been a symbol of wealth and luxury. But have you ever wondered how this precious metal is purified and transformed into the glittering bars and coins we all admire? Welcome to the fascinating world of gold refinery machines, where technology and chemistry work hand in hand to produce pure gold. In this article, we’ll explore the intricate processes and advanced technologies used in gold refineries, with a special mention of “K-Jhil Scientific,” a renowned manufacturer of chemical process systems. Whether you’re an industry professional or just curious about the process, this comprehensive guide will enlighten you on every aspect of gold refining.

Introduction to Gold Refining

Gold refining is a crucial process that transforms raw gold into pure gold, suitable for various applications such as jewelry, electronics, and investment. The technology behind gold refinery machines is a blend of chemistry, physics, and engineering, ensuring that the gold produced meets the highest standards of purity.

What is a Gold Refinery?

A gold refinery is an industrial facility where gold is purified and processed. These refineries use various techniques to remove impurities from raw gold, resulting in high-purity gold products. The process involves both chemical and mechanical methods to achieve the desired purity levels.

The Importance of Gold Refining

Why is gold refining so important? Simply put, refined gold is essential for various industries. Jewelry makers need high-purity gold to create exquisite pieces, while the electronics industry relies on gold’s conductivity. Investment-grade gold must also meet strict purity standards to be valuable. Refining ensures that gold meets these diverse requirements, making it a critical part of the gold supply chain.

Basic Steps in Gold Refining

- Collection and Initial Processing: Raw gold is collected and initially processed to remove larger impurities.

- Chemical Treatment: Chemicals such as aqua regia or chlorine gas are used to dissolve and separate gold from other metals.

- Precipitation: Gold is precipitated out of the solution and collected.

- Melting and Casting: The purified gold is melted and cast into bars or other forms.

- Final Purification: Further refining processes are applied to achieve the highest levels of purity.

Types of Gold Refinery Machines

Gold refinery machines come in various types, each designed for specific stages of the refining process:

- Electrolytic Refining Machines: Use an electrolytic process to purify gold.

- Induction Melting Furnaces: Melt gold at high temperatures for casting.

- Chemical Refining Systems: Utilize chemical processes to extract and purify gold.

- Vacuum Distillation Units: Remove impurities under vacuum conditions.

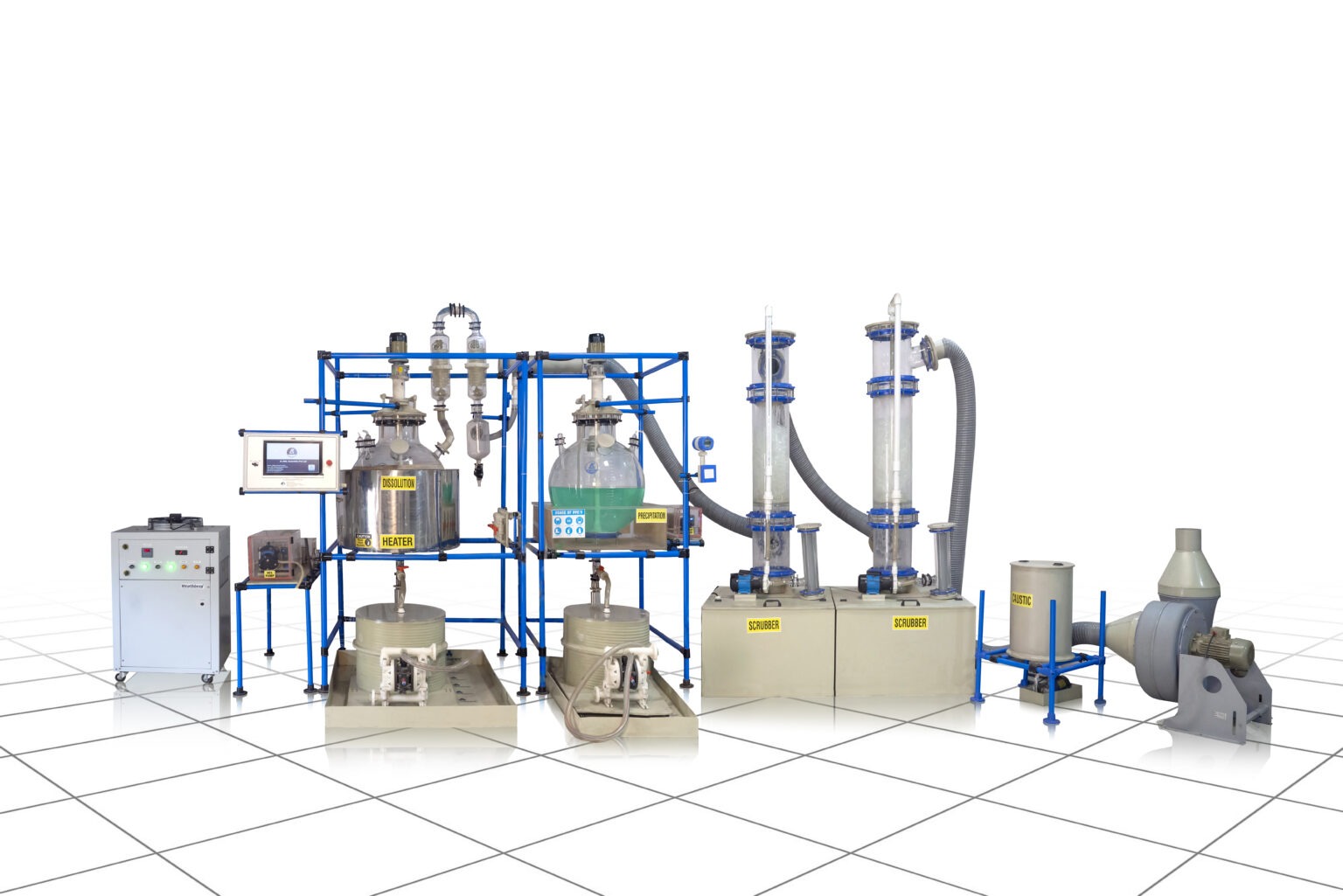

The Role of K-Jhil Scientific

K-Jhil Scientific is a leading manufacturer of chemical process systems, including those used in gold refining. Their advanced technology and innovative solutions have set new standards in the industry. By integrating cutting-edge techniques with robust engineering, K-Jhil Scientific ensures that gold refineries achieve maximum efficiency and purity.

Chemical Processes in Gold Refining

Chemical refining involves several steps and compounds:

- Aqua Regia: A mixture of nitric acid and hydrochloric acid used to dissolve gold.

- Chlorine Gas: Used in the Miller process to purify gold by converting impurities to chlorides.

- Precipitation Agents: Chemicals such as sodium metabisulfite are used to precipitate gold from solutions.

These processes are carefully controlled to ensure that the final product is free from contaminants.

Mechanical Processes in Gold Refining

Mechanical refining involves physical processes such as:

- Crushing and Grinding: Breaking down gold ore into smaller particles.

- Milling: Further reducing the particle size to enhance the chemical reactions.

- Filtration: Removing solid impurities from the gold solution.

These steps complement the chemical processes, ensuring thorough purification.

Advancements in Gold Refinery Technology

The technology behind gold refinery machines is continually evolving. Recent advancements include:

- Automated Systems: Reducing human error and increasing efficiency.

- Green Chemistry: Using environmentally friendly chemicals and processes.

- Real-Time Monitoring: Advanced sensors and software to monitor and control the refining process.

These innovations make gold refining more efficient, safe, and sustainable.

Safety Measures in Gold Refining

Gold refining involves hazardous chemicals and high temperatures, making safety paramount. Essential safety measures include:

- Protective Gear: Workers must wear appropriate protective clothing and equipment.

- Ventilation Systems: Proper ventilation to handle fumes and gases.

- Emergency Procedures: Clear protocols for dealing with accidents and spills.

Implementing these measures helps protect workers and the environment.

Environmental Impact of Gold Refining

Gold refining can have significant environmental impacts if not managed properly. Key concerns include:

- Chemical Waste: Proper disposal and treatment of chemical byproducts.

- Energy Consumption: Reducing the energy footprint of refining processes.

- Water Usage: Minimizing water use and preventing contamination.

K-Jhil Scientific is at the forefront of developing eco-friendly refining technologies, addressing these environmental challenges.

Cost Considerations in Gold Refining

The cost of gold refining depends on several factors:

- Raw Material Quality: Higher impurity levels require more extensive refining.

- Technology Used: Advanced systems can be more expensive but offer higher efficiency.

- Scale of Operation: Larger refineries benefit from economies of scale.

Balancing these factors helps refineries optimize costs without compromising on quality.

Choosing the Right Gold Refinery Machine

Selecting the right gold refinery machine is crucial for achieving optimal results. Considerations include:

- Capacity: Ensure the machine can handle the required volume.

- Technology: Choose a machine with the latest features and capabilities.

- Reliability: Opt for reputable manufacturers like K-Jhil Scientific for dependable equipment.

Making an informed choice ensures efficient and effective gold refining.

Maintenance and Longevity of Refinery Machines

Regular maintenance is essential for the longevity of gold refinery machines. Key practices include:

- Routine Inspections: Regular checks to identify and address issues early.

- Cleaning and Calibration: Ensuring machines are clean and properly calibrated.

- Manufacturer Support: Relying on manufacturer support for parts and technical assistance.

Proper maintenance ensures that refinery machines operate smoothly and last longer.

Future Trends in Gold Refining

The future of gold refining looks promising with trends such as:

- Digital Integration: Use of digital tools for process optimization.

- Sustainable Practices: Emphasis on environmentally friendly refining methods.

- Global Collaboration: International cooperation to set industry standards and share innovations.

These trends will shape the future of gold refining, making it more efficient and sustainable.

Conclusion

Gold refining is a complex and fascinating process that transforms raw gold into pure, valuable metal. With advancements in technology and a focus on sustainability, the industry continues to evolve. K-Jhil Scientific plays a crucial role in this evolution, providing cutting-edge solutions that enhance the efficiency and quality of gold refining. Whether you’re involved in the industry or just curious, understanding the technology behind gold refinery machines offers a deeper appreciation of this vital process.

FAQs

1. What is the purpose of a gold refinery machine?

A gold refinery machine purifies raw gold, removing impurities to produce high-purity gold for various applications.

2. How does K-Jhil Scientific contribute to gold refining?

K-Jhil Scientific manufactures advanced chemical process systems that enhance the efficiency and quality of gold refining processes.

3. What safety measures are necessary in gold refining?

Essential safety measures include wearing protective gear, proper ventilation, and having clear emergency procedures to handle accidents and spills.

4. How does gold refining impact the environment?

Gold refining can have significant environmental impacts if not managed properly, including chemical waste, energy consumption, and water usage. Sustainable practices and technologies help mitigate these effects.

5. What are the latest advancements in gold refinery technology?

Recent advancements include automated systems, green chemistry, and real-time monitoring, all of which improve efficiency, safety, and sustainability in gold refining.