What is Sand Casting?

Sand casting is a manufacturing process where molten metal is poured into a mold made from a sand mixture to create a specific shape. Once the metal cools and solidifies, the sand mold is broken apart to retrieve the finished metal part.

How Does Sand Casting Work? (Step-by-Step)

-

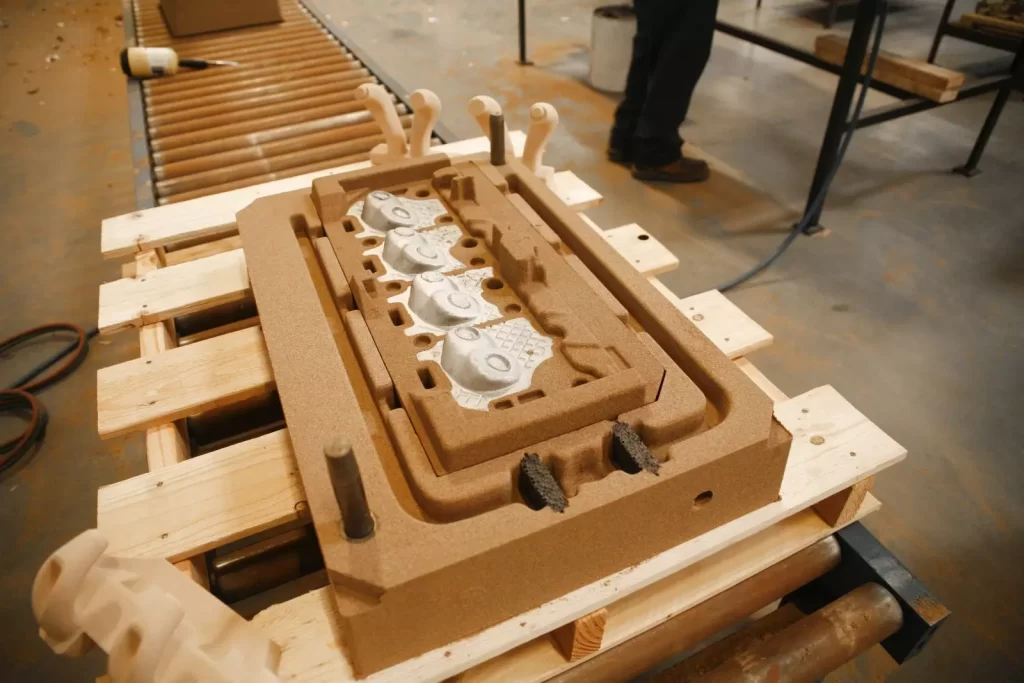

Pattern Creation

A pattern, which is a replica of the final product, is made out of wood, plastic, or metal. This pattern helps create the mold cavity. -

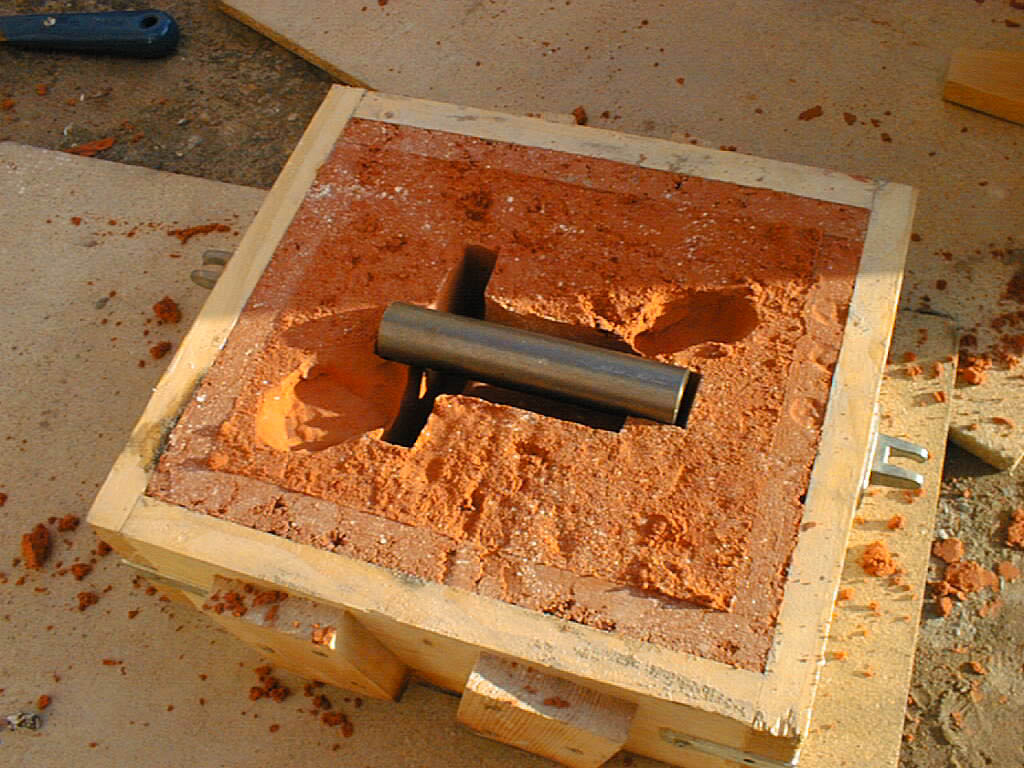

Mold Preparation

The pattern is placed inside a box (called a flask), and sand mixed with a binder (like clay) is packed tightly around it. This creates the mold. -

Removing the Pattern

Once the sand is packed, the pattern is carefully removed, leaving behind a cavity in the shape of the desired part. -

Pouring Molten Metal

Molten metal (steel, aluminum, cast iron, etc.) is poured into this cavity. -

Cooling and Solidification

The metal cools down and solidifies into the shape of the mold. -

Breaking the Mold

After cooling, the sand mold is broken apart to retrieve the cast metal part. -

Cleaning and Finishing

The cast part is cleaned to remove leftover sand and may go through finishing processes like grinding, machining, or heat treatment to get the final specifications.

Why is Sand Casting Popular?

-

Cost-Effective: The sand used for molds is cheap and reusable, making it economical for small to medium production runs.

-

Flexible for Complex Shapes: It can create complex and large parts that other methods might struggle with.

-

Material Versatility: Works with almost all metals, from aluminum to steel and cast iron.

-

Quick Setup: Compared to other casting methods, making sand molds is faster and easier.

Downsides of Sand Casting

-

Surface Finish: Usually rougher compared to other casting techniques, so parts often need additional finishing.

-

Dimensional Accuracy: Not as precise as methods like die casting.

-

One-Time Mold Use: Sand molds are destroyed to remove the part, so they aren’t reusable.

Industries That Use Sand Casting

-

Automotive parts like engine blocks and cylinder heads

-

Marine components

-

Heavy machinery parts

-

Art and decorative metalwork