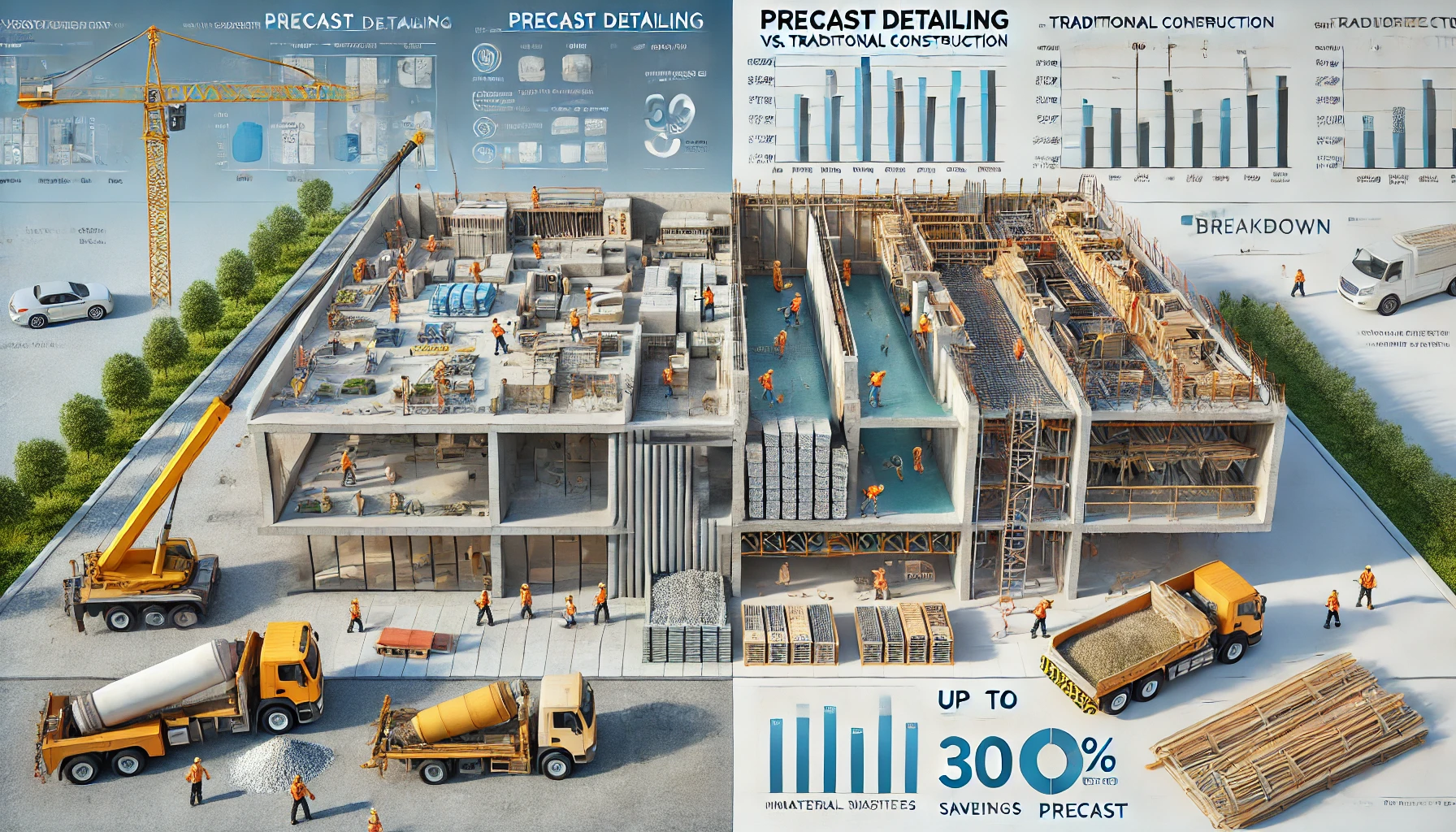

Time is money in construction. Whether it’s a skyscraper, a bridge, or a residential project, delays and inefficiencies eat into your budget. The debate between precast detailing and traditional construction has never been more relevant—which method actually saves you more?

The Verdict: Precast Wins on Cost & Speed

Precast detailing can reduce overall construction costs by up to 30%, cut project timelines in half, and lower labor expenses significantly. Traditional construction, on the other hand, often leads to budget overruns due to material waste, labor inefficiencies, and weather delays.

In this guide, we’ll break down the numbers, expose hidden costs, and give you real-world insights into why precast detailing is the smart financial choice for modern construction.

Key Cost-Saving Takeaways

✅ Precast detailing is up to 30% cheaper than traditional construction.

✅ Projects finish 50% faster with precast.

✅ Material waste is reduced by 15%, thanks to factory-controlled precision.

✅ Labor costs drop significantly with off-site production.

✅ Precast structures last longer and require less maintenance.

What is Precast Detailing?

Precast detailing is a modern construction method where concrete components are manufactured off-site in a controlled environment. These pieces are then transported to the site and assembled efficiently—like giant LEGO blocks.

Why This Saves Money:

✔ Minimal On-Site Labor: Most of the work is done in a factory.

✔ No Weather Delays: Unlike traditional concrete, precast doesn’t depend on site conditions.

✔ Lower Material Waste: Every piece is precisely measured, reducing overuse.

✔ Speed: Precast structures go up fast—cutting financing and labor costs.

📌 Want to see real-world cost comparisons? Keep reading!

The Hidden Costs of Traditional Construction

Traditional construction—pouring concrete on-site—seems straightforward, but is riddled with inefficiencies:

❌ High Labor Costs: More workers are needed for extended periods.

❌ Weather Delays: Rain, heat, and cold can push back timelines, increasing expenses.

❌ Material Waste: Up to 15% more concrete is wasted due to miscalculations and errors.

❌ Extended Build Times: Concrete must cure in phases, delaying progress.

A delay of just one month on a large project can add thousands in extra labor costs—costs that precast construction avoids.

Precast vs. Traditional: Real Cost Savings

| Cost Factor | Precast Detailing | Traditional Construction | Savings (%) |

|---|---|---|---|

| Material Costs | Lower (bulk production) | Higher (onsite mixing) | 15% |

| Labor Costs | Lower (factory-controlled) | Higher (onsite workers) | 30-40% |

| Construction Time | 50% Faster | Slower (weather, labor) | 50% |

| Maintenance Costs | Lower | Higher | 20% |

| Waste Reduction | High Efficiency | High Waste | 15% |

🔍 Potential Savings: Up to 30% on total project costs!

📖 For a detailed breakdown of quality control in precast construction, check out this report.

Why Precast is the Speed & Efficiency Champion

Every extra day in construction equals extra costs. Here’s how precast helps:

✔ 50% Faster Timelines: No waiting for concrete to cure, so projects move quickly.

✔ Fewer Workers Needed: Lower payroll expenses.

✔ Better Quality Control: No costly rework or material waste.

📌 A company using precast finished their high-rise in half the time, saving millions!

Precast is Built to Last (With Lower Lifetime Costs)

Precast isn’t just cheaper upfront—it saves money long-term.

✔ Stronger than traditional concrete, thanks to controlled manufacturing.

✔ Resistant to weather, corrosion, and wear.

✔ Lower maintenance and repair costs over decades.

💡 Example: A precast bridge in the U.S. has lasted over 50 years with minimal upkeep, saving taxpayers millions.

FAQs: Answering Your Precast Cost Questions

1. How much money can I save by using precast?

👉 Up to 30% of total construction costs, mainly due to reduced labor and material waste.

2. Is precast concrete as strong as traditional concrete?

👉 Yes! Precast is often stronger because it’s made in a controlled environment, ensuring better quality and consistency.

3. Does precast require special installation?

👉 Not really. It’s just different—but easier and faster than traditional construction.

4. Are there hidden costs with precast?

👉 The initial price may seem higher, but you save BIG on labor, waste, and time—making it the cheaper option overall.

5. Can precast be used in home construction?

👉 Absolutely! Many modern homes use precast panels to save time, reduce costs, and improve energy efficiency.

Final Verdict: Why Precast is the Future of Cost Savings

✅ Saves money—up to 30% per project.

✅ Faster, stronger, and more efficient than traditional methods.

✅ Less waste, lower labor costs, and better durability mean long-term savings.

💡 Considering precast for your next project? Explore our precast detailing services and see how we can help you cut costs and build smarter!

Learn about Construction Delays and Dispute Mitigation: Strategies for a Successful Project